Cutting machining

Cutting machining is one of the key technologies in industry, allowing for precise shaping and forming of materials such as metals, plastics, and composites. This process involves removing excess material from a workpiece using cutting tools to achieve the desired shape and dimensions.

In cutting machining, various methods are distinguished, such as milling, turning, drilling, and grinding. Each method has its unique applications and advantages, making cutting machining highly versatile. Modern CNC machines enable high precision and repeatability, which is crucial for producing components with complex shapes.

Cutting machining is used in many industries, from automotive and aerospace to electronics. It allows for the creation of both single prototypes and large-scale productions. It is important to note that the proper selection of tools and machining parameters is crucial for the quality of the final product.

Obróbka skrawaniem

CNC Milling *

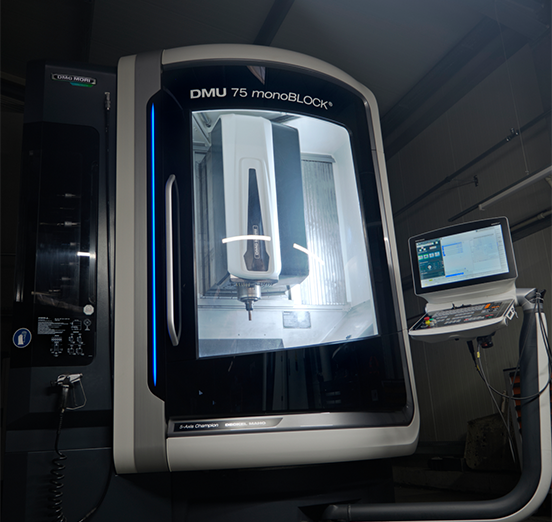

We have an advanced 5-axis machining center from DMG MORI, as well as conventional milling machines, which enable us to execute even the most complex projects with unparalleled precision.

* – New service realized under the "Success Vouchers" project.

| DMG MORI DMU 75 monoBLOCK: | |||

| Maximum workpiece dimensions: | X = 750mm | Y = 650 mm | Z = 560 mm |

| CONVENTIONAL MILLING MACHINES: | |||

| Maximum workpiece dimensions: | X = 750 mm | Y = 400 mm | Z = 400 mm |

Turning

Our offerings also include turning using conventional lathes.

| Maximum turning length: | 1000 mm |

| Maximum turning diameter: | 300 mm |

Surface grinding

Jest to kluczowy proces obróbki mechanicznej, który zapewnia doskonałą jakość powierzchni oraz osiąganie tolerancji rzędu mikronów.

| Table dimensions: | X = 600 mm | Y = 400 mm | Z = 350 mm |

We have licensed software such as:

Contact form

Our workshop