Electrical discharge machining

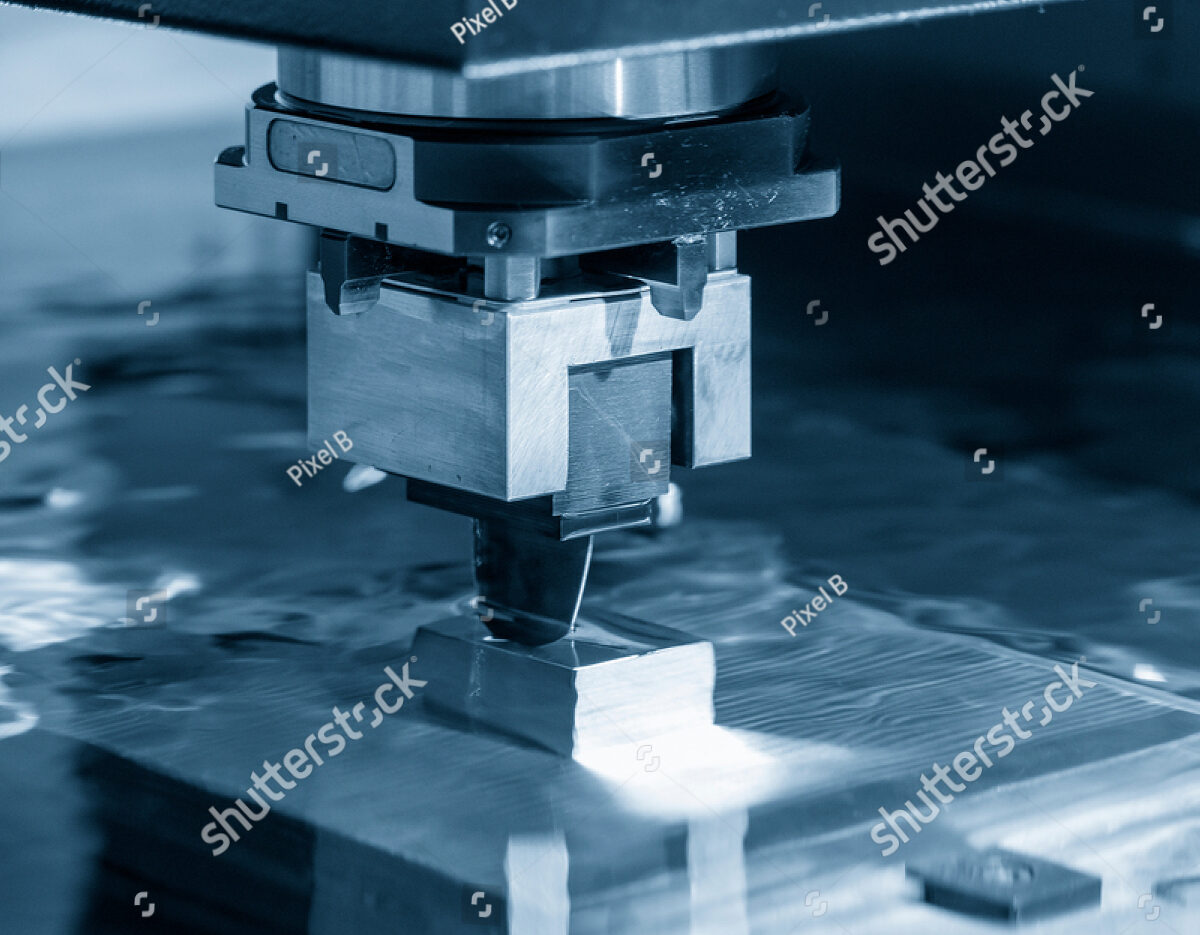

Electrical discharge machining (EDM) is an advanced machining method that uses the phenomenon of electrical erosion to precisely shape materials. This process involves removing material from a workpiece through electrical sparks generated between an electrode and the material. This technology allows for the creation of complex shapes and details that are difficult to achieve with other machining methods.

In EDM, electrodes made from conductive materials such as copper or graphite are precisely shaped to match the desired contours. This process is particularly effective for machining hard materials, such as tool steel or composite materials, making it an ideal solution in industries such as automotive, aerospace, and tool manufacturing.

We have a GF Machining Solutions

FORM E600 die-sinking EDM center.

| Maximum workpiece dimensions: | X = 1000 mm | Y = 700 mm | Z = 400 mm |

| Axis travels: | X = 600 mm | Y = 400 mm | Z = 400 mm |

| Maximum workpiece weight: | 1000 kg | ||

| Soft: | v |